The quality of accessories impacts your productivity

Only high-quality accessories can enhance your efficiency by achieving more than the sum of their parts. We understand what truly matters in the CNC industry. Let's explore it together.

We offer an extensive array of accessories for the CNC industry, encompassing everything from commonly used inserts and a variety of compatible tool carts

to essential safety products such as work shoes. When you shop with us, Each accessory is carefully selected and tested to ensure the highest quality,

providing you with the assurance of reliability and performance. By working with us, you can effectively optimize your machining operations.

The accessories displayed on our website are just a fraction of the extensive CNC accessories we offer. Please contact us to receive our complete CNC accessories catalog.

Contact Us Now

Blow Gun Chip Guarding Shield

Enhance your machining accuracy with our high-quality CNC milling inserts. Designed for durability and precision, our inserts ensure optimal performance and extended tool life, making them ideal for various materials and applications.

See more

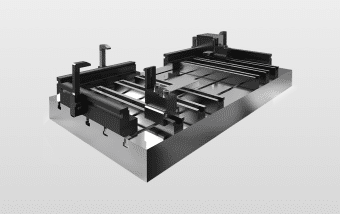

CNC Tool Carts

Organize your workspace efficiently with our robust CNC tool carts. These carts are designed to provide convenient storage and easy access to all your essential tools, helping you maintain a clutter-free and productive environment.

See more

Mold Steel

Our premium mold steel is engineered for exceptional strength and durability. Perfect for creating precise molds, this steel offers excellent machinability and resistance to wear, ensuring long-lasting performance in your CNC operations.

See more

Industrial Clamps

Secure your workpieces with our reliable industrial clamps. Designed for maximum stability and ease of use, these clamps are essential for maintaining accuracy and safety in your CNC processes.

See more

Safety Shoes

Protect yourself with our range of durable safety shoes, specifically designed for the CNC industry. These shoes offer superior protection against workplace hazards while ensuring comfort throughout long working hours.

See more

Other Accessories

Discover our comprehensive range of CNC accessories, including everything from coolant systems to measuring tools. Each accessory is crafted to enhance the efficiency and precision of your CNC operations, ensuring you have all the tools you need for success.

See more

Watch the video below to discover the range of accessories offered by ASIATOOLS and see how our accessories perform. The accessories shown in the video are representative of the high quality you can expect to receive.

Only high-quality accessories can enhance your efficiency by achieving more than the sum of their parts. We understand what truly matters in the CNC industry. Let's explore it together.

What types of cutting tools do I need for my CNC machine?

The type of cutting tools required depends on the material you are working with and the specific operations you are performing. Common types include end mills, drills, and turning tools, made from materials like carbide, high-speed steel, or ceramics for different durability and precision needs.

How often should I replace my tool inserts?

The lifespan of tool inserts varies based on the material being cut, the cutting conditions, and the quality of the insert. Generally, you should replace inserts once you notice a decline in cutting performance or visible wear. Regular inspection and timely replacement ensure optimal cutting efficiency and quality.

How do I choose the right tool cart for my CNC shop?

Selecting the right tool cart involves considering factors such as the size of your CNC machines, the number of tools you need to store, and the layout of your workspace. Opt for a tool cart that offers adequate capacity, organized storage solutions, and mobility to facilitate easy access during operations.

Can I use the same cutting tools for different materials?

While some cutting tools are versatile enough to handle various materials, it’s essential to use tools specifically designed for the material you are working with to maximize tool life and achieve the best results. Different coatings and tool geometries may be required to effectively cut through different materials.

What are the signs that my cutting tools need sharpening or replacing?

Common signs include an increase in machine chatter, poor finish on the cut material, and an unexpected increase in power consumption. Regularly check your tools for wear and damage, and either re-sharpen them if possible or replace them to maintain cutting efficiency.

If you have any questions about CNC machines, accessories, or the industry, feel free to reach out to us!

CONTACT US TODAY