Powerful cutting

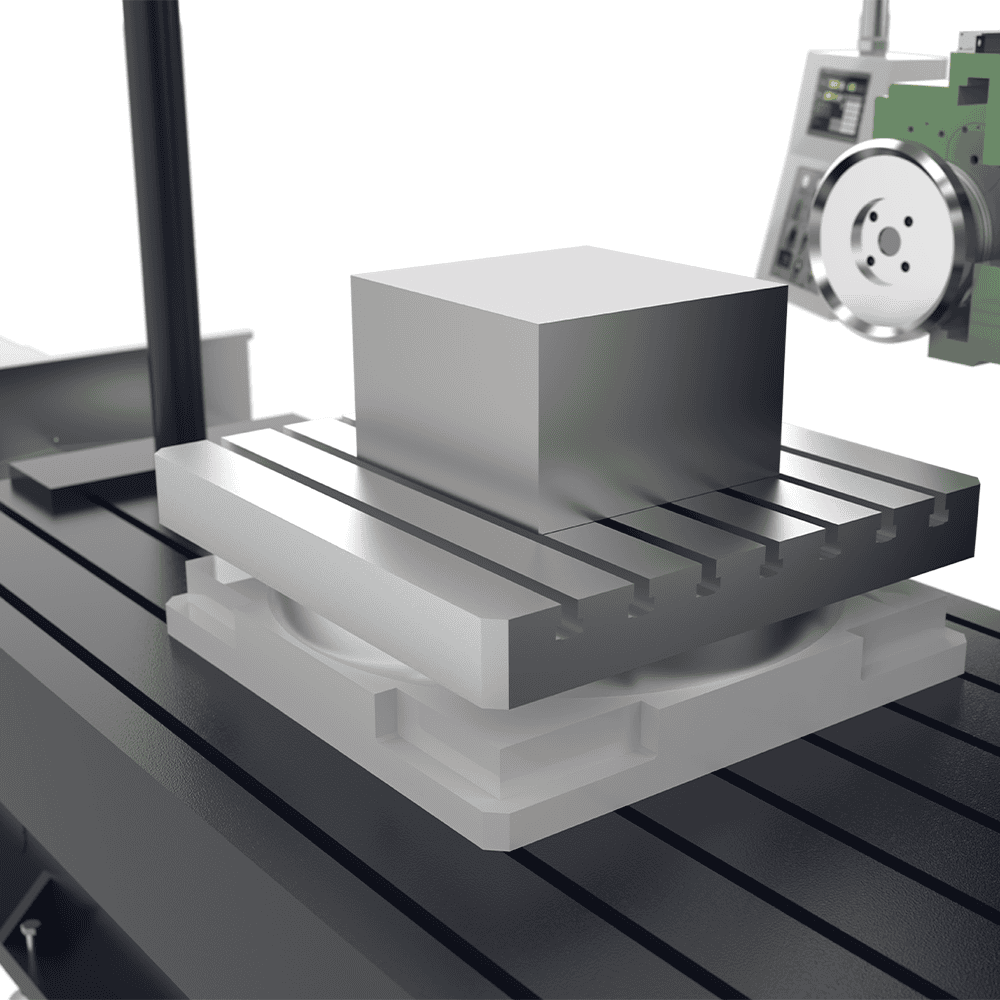

The turntable can mill the four end facesof the workpiece. The milling force is strong, which canmeet the machining requirements of parts.

Single-column lifting precision milling machine, with a large processing range of end milling machines. Suitable for end cutting of large mold bases, large steel, and other metal materials cutting, widely used in machinery manufacturing. It is especially suitable for milling the end face of the mold industry, mold embryo, mold material, and plastic mold frame. It can be used to mill both ends of super-long workpieces.

Powerful cutting

The turntable can mill the four end facesof the workpiece. The milling force is strong, which canmeet the machining requirements of parts.

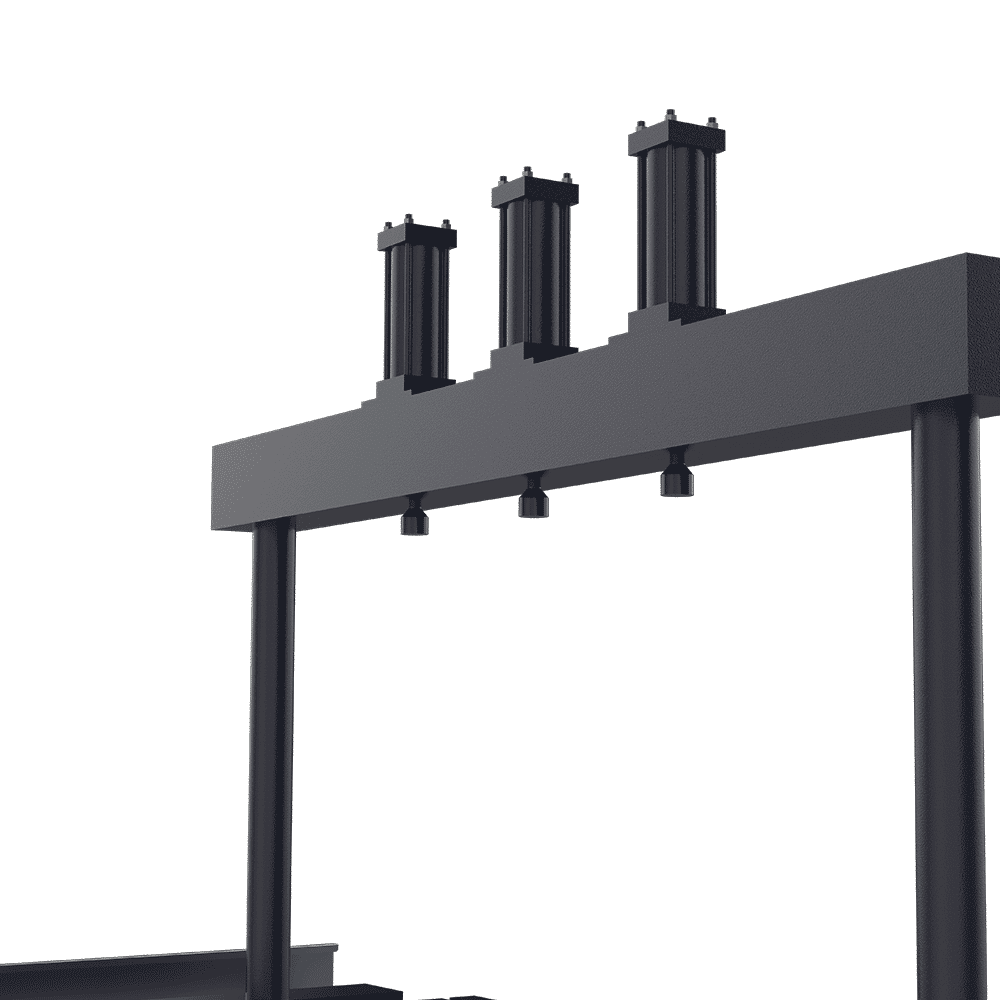

Hydraulic gantry, good stability

Hydraulic gantry, equipped with a three-cylinder pressing rack, pressing material the method is stable and stable.

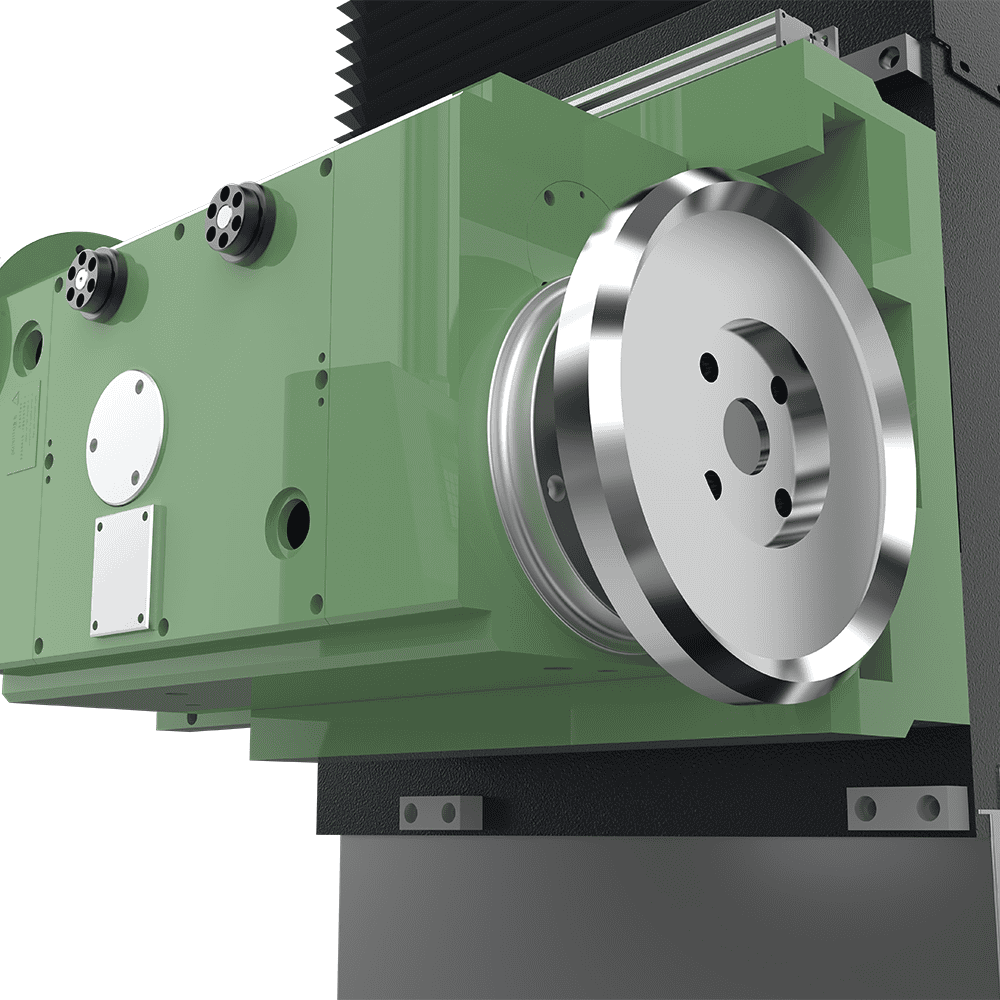

Precision milling and low noise

The milling unit adopts gear transmission, and the cutting and milling surface accuracy is high. Noise is low.

Strong rigidity

The whole machine is rigid, and not easy to damage. Easy to maintain, and functional Variety, large geometric size, ideal for machining prepare.

| Items | Value | Unit | |

| Processing capacity | Maximum machining length | 2100(can't rotate the workpiece) | mm |

| 1450(can rotate the workpiece) | |||

| Maximum processing height | 700 | ||

| Workpiece width | 750-1450 | ||

| Worktable | Worktable size | 1200*2500 | mm |

| Max. load capacity | 6000 | KG | |

| Precision pneumatic rotary table | 800*800 | / | |

| Gear-driven spindle | Spindle speed | 75-505 | rpm |

| Motor power | 11 | KW | |

| Spindle taper | BT50(7:24) | mm | |

| Cutter diameter | ∅250 | mm | |

| Number of spindle shift segments | 6 | grade | |

| Feed rate | X-axis feed rate | Infinitely variable speed0-5000 | mm / min |

| Y-axis feed rate | Infinitely variable speed0-2000 | mm / min | |

| Z-axis feed rate | Infinitely variable speed0-500 | mm / min | |

| Power | X/Y/Z axis motor | 5.5/2.2/0.4 | KW |

| Size & weight | Machine weight | About12500 | KG |

| Machine size ( L*W*H ) | 6826*2700*3300 | mm | |

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,Asiatools Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

FANUC CONTROLLER

Fanuc oi-MF Plus 10.4'' Touch screen control panel Fanuc oi-MF Plus 10.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

MITSUBISHI CONTROLLER

Mitsubishi-M80 series 10.4''Touch screen control panel Mitsubishi-E80 series 8.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

CHINA CONTROLLER

JK 15'' Touch screen control panle. Easy operating program. Big and simple operating interface as smart phone touchscreen.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly