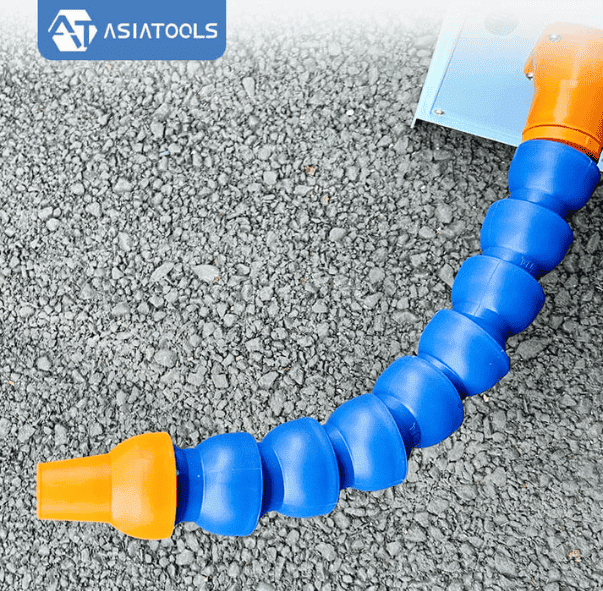

Durable Construction

Crafted from high-quality PP material, offering exceptional wear resistance and rigidity, ensuring a long service life.

ASIATOOLS High-Speed CNC Chip Blower efficiently removes chips and coolant during production without interruptions. Installed in the spindle column, it fits various CNC milling, drilling, and lathe machines, including popular brands like HAAS, Mazak, DMG Mori, Okuma, Makino, Hardinge, and Mori Seiki. Essential for every workshop, it boosts part output, improves quality, enhances tool performance, and reduces downtime significantly.

Durable Construction

Crafted from high-quality PP material, offering exceptional wear resistance and rigidity, ensuring a long service life.

Versatile Applications

Ideal for use in CNC machining centers, drilling and tapping machines, milling machines, and more.

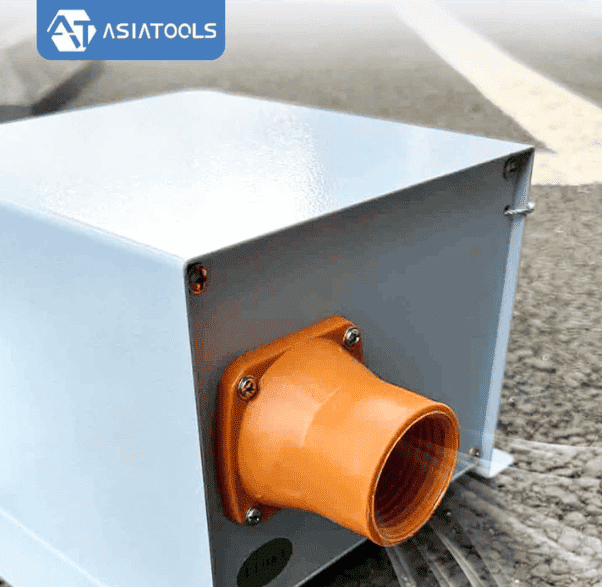

Powerful Performance

Large air outlet delivers strong airflow, significantly enhancing heat dissipation.

Protection

Provides deep chip cleaning, all-around protection for machinery and tools.

| Model | AT-01 (Black) | AT-02(White) | Unit |

| Speed | 24000 | 18000 | rpm |

| Voltage | 220 | 220 | v |

| Power | 0.35 | 0.25 | kw |

| Depth of blowing | 600 | 500 | mm |

| Air outlet diameter | 23 | 23 | mm |

| Weight | 6.5 | 6.5 | kg |

| Application | CNC machine/CNC drilling-tapping machine/chip blowing | CNC machine/CNC drilling-tapping machine/chip blowing |

Our commitment to clients extends well beyond the purchase of CNC accessories. We provide comprehensive after-sales support, including expert installation guidance and hands-on training sessions, to ensure your team is fully prepared to use and maintain our products effectively. Our dedicated customer service and technical support teams are always available to assist you, offering solutions and advice to ensure your operations remain efficient and uninterrupted.

Q: What is a CNC chip blower used for?

A: A CNC chip blower is used to remove chips and debris from the machining area, ensuring a clean and safe environment for CNC operations. It helps in maintaining the efficiency and precision of the machine.

Q: How does a CNC chip blower work?

A: CNC chip blowers typically use air pressure to blow chips away from the cutting area. They can be manually operated or integrated into the CNC machine for automatic operation during or after the machining process.

Q: What are the benefits of using a CNC chip blower?

A: Benefits include reduced machine downtime, enhanced safety, improved tool life, and a cleaner working environment. It eliminates the need for manual cleaning and allows for continuous production.

Q: Are CNC chip blowers energy efficient?

A: Yes, many CNC chip blowers are designed to be energy efficient, often not requiring additional equipment like air compressors. This makes them environmentally friendly and cost-effective.

Q: Can CNC chip blowers be used with any CNC machine?

A: Most CNC chip blowers are versatile and can be used with various types of CNC machines, such as machining centers, drilling machines, and milling machines. However, it's important to ensure compatibility with specific machine models.

Q: Is it easy to install a CNC chip blower?

A: Many CNC chip blowers are designed for easy installation, often with integrated designs that do not require external power supplies. This simplifies the setup process.

Q: Do CNC chip blowers require maintenance?

A: Like any equipment, regular maintenance is advisable to ensure optimal performance. This may include checking air pressure levels and cleaning any buildup of chips in the blower itself.