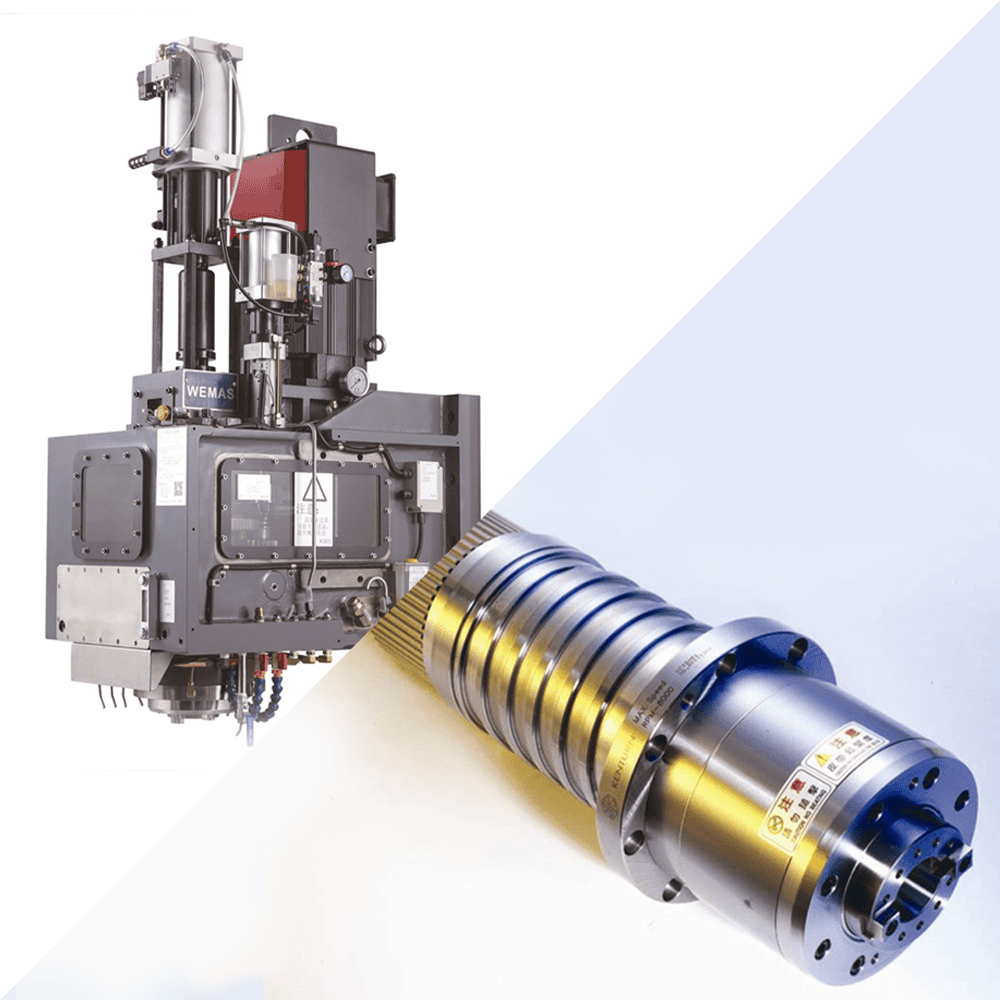

Gear box/belt driven

Improves processing efficiency. High-quality electrical components with high safety factors and long durability.

The Z-axis uses a high-rigidity hard way, while the X & Y axes employ a high-speed linear guideway, ensuring minimal vibration during a high-speed feed and eliminating creeping at low speeds. It can provide single-setup complete part machining such as milling, drilling, tapping, and other operations, suitable for machining parts such as medium and small-sized hardware, box, plate, disk, and shell-type components.

Gear box/belt driven

Improves processing efficiency. High-quality electrical components with high safety factors and long durability.

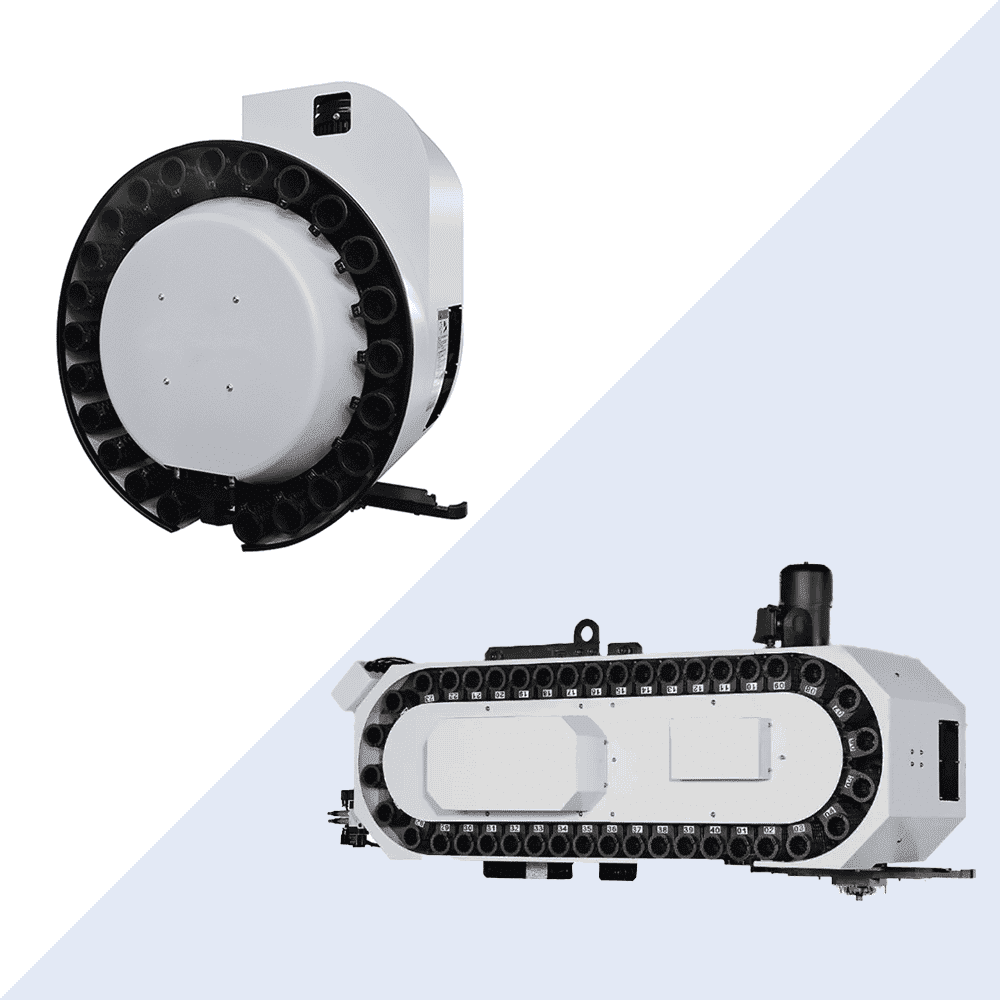

Tool magazine

Fast tool change speed suitable for batch processing.

CNC system

Human interaction design, high compatibility and good after-sales service.

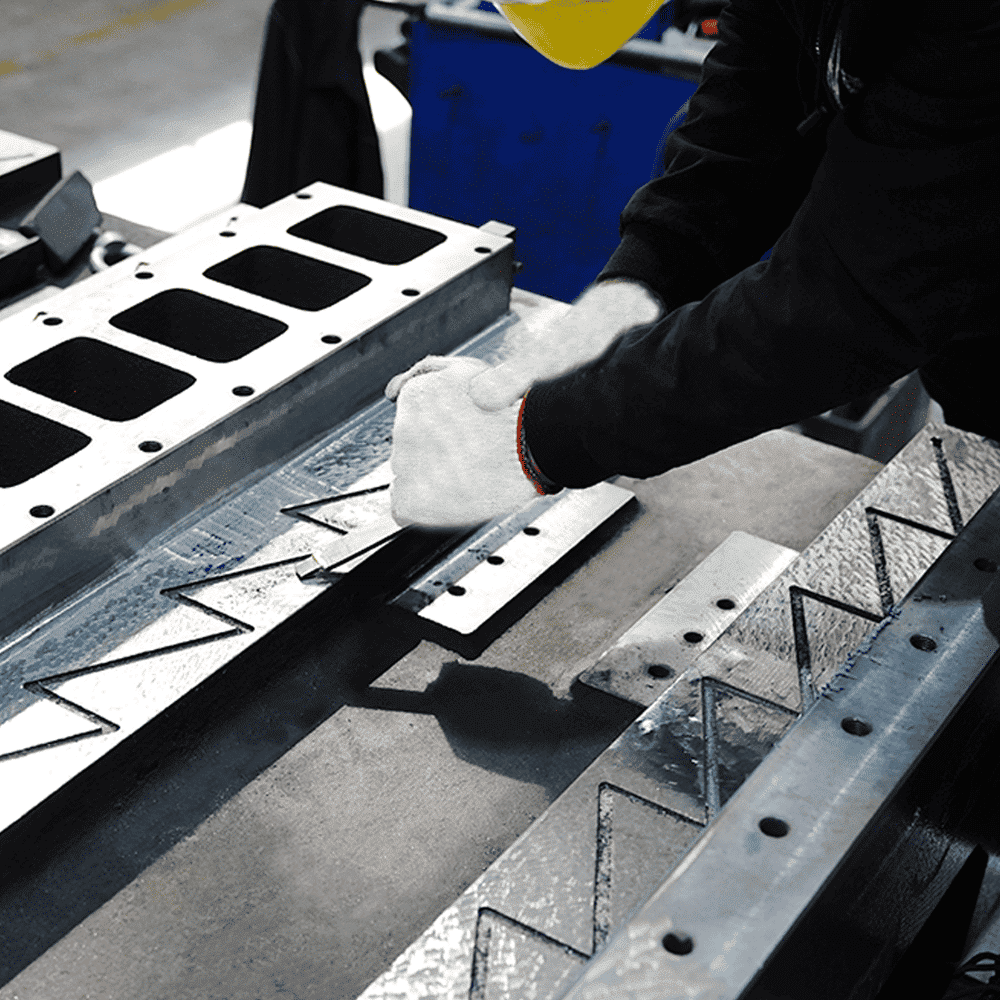

Machine casting

Adopt scraping technology to ensure machine tool accuracy.

| Items | Value | Unit | |

| Travel | X-axis travel | 1300 | mm |

| Y-axis travel | 700 | mm | |

| Z-axis travel | 700 | mm | |

| Worktable | Worktable size | 1350*700 | mm |

| Max. load capacity | 1500 | KG | |

| T-slot | 5-18*122 | mm | |

| Spindle | Drive type | Belt type(St.)/Gear box(Op.) | / |

| Tool holder specifications | BT50-190 | / | |

| Distance from spindle nose to table | 127-827 | mm | |

| Distance from spindle center to column | 810 | mm | |

| Spindle speed (MAX.) | 6000 | r/min | |

| Feed rate | X/Y/Z rapid feed rate (MAX.) | 16/16/12 | mm |

| X/Y/Z cutting feed rate (MAX.) | 12/12/10 | ||

| Tool magazine parameters | ATC capacity | 24(St.)/32/64(Op.) | T |

| Tool Dia(full tool) × tool length | φ110 × 350 | mm | |

| Tool Dia(adjacent empty) × tool length | φ220 × 350 | ||

| Max. tool weight | 15 | KG | |

| Accuracy | Positioning accuracy (X/Y/Z) | 0.02/1000 | mm |

| Repeat positioning accuracy (X/Y/Z) | 0.015/1000 | ||

| Size & weight | Machine space | 4100*4300*3400 | mm |

| Machine weight | 11.5 | T | |

Contact us for more information on our Custom Made Machine Tools Solutions for complex workpieces. When you need high rigidity, efficiency and powerful machines,Asiatools Machinery gets you going!

To meet your different processing needs, we provide three widely used systems on the market for you to choose.

FANUC CONTROLLER

Fanuc oi-MF Plus 10.4'' Touch screen control panel Fanuc oi-MF Plus 10.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

MITSUBISHI CONTROLLER

Mitsubishi-M80 series 10.4''Touch screen control panel Mitsubishi-E80 series 8.4'' keyboard control panel. The simple and functional panel, the comfortable operational functional keyboard panel. User-friendly interface and Easy conversational operating program.

CHINA CONTROLLER

JK 15'' Touch screen control panle. Easy operating program. Big and simple operating interface as smart phone touchscreen.Our relationship with clients doesn't end with the sale. We offer comprehensive after-sales support that encompasses everything from expert installation services to hands-on training sessions, ensuring your team is fully equipped to operate and maintain our machinery. Our responsive customer service and technical support are always at your disposal, providing solutions and assistance to keep your operations running smoothly