In modern automotive manufacturing, the use of horizontal machining center is becoming increasingly widespread. It not only improves production efficiency, but also enhances product quality and design flexibility. Today, we will delve into the specific applications of horizontal machining center in the automotive industry.

The advantages of horizontal machining center:

Firstly, from a design perspective, horizontal machining center provide great convenience for automotive manufacturing. Designers can use horizontal machining center for complex 3D model design and simulation analysis. For example, the body, seats, dashboard and other components of a car can be accurately modeled and simulated through horizontal machining center to ensure the rationality and feasibility of the design scheme.

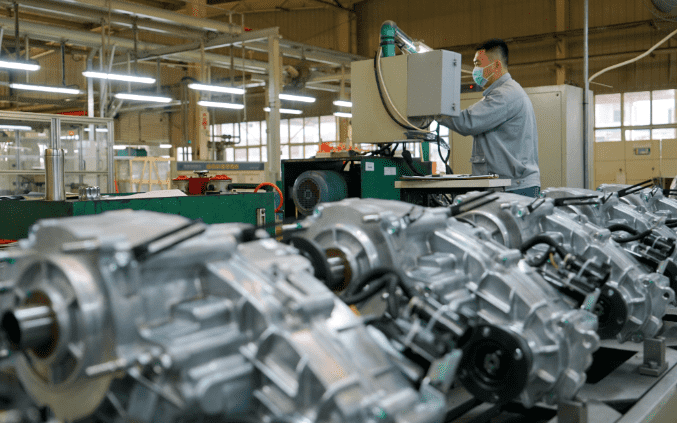

Secondly, from the perspective of the manufacturing industry, horizontal machining center play a crucial role in the manufacturing process of automotive components. For example, the cylinder block, crankshaft, connecting rod and other components of the engine, as well as the gears, bearings, housing and other components of the transmission, can be finely cut and ground through horizontal machining center.

Product recommendation:WJ-1815 horizontal machining center

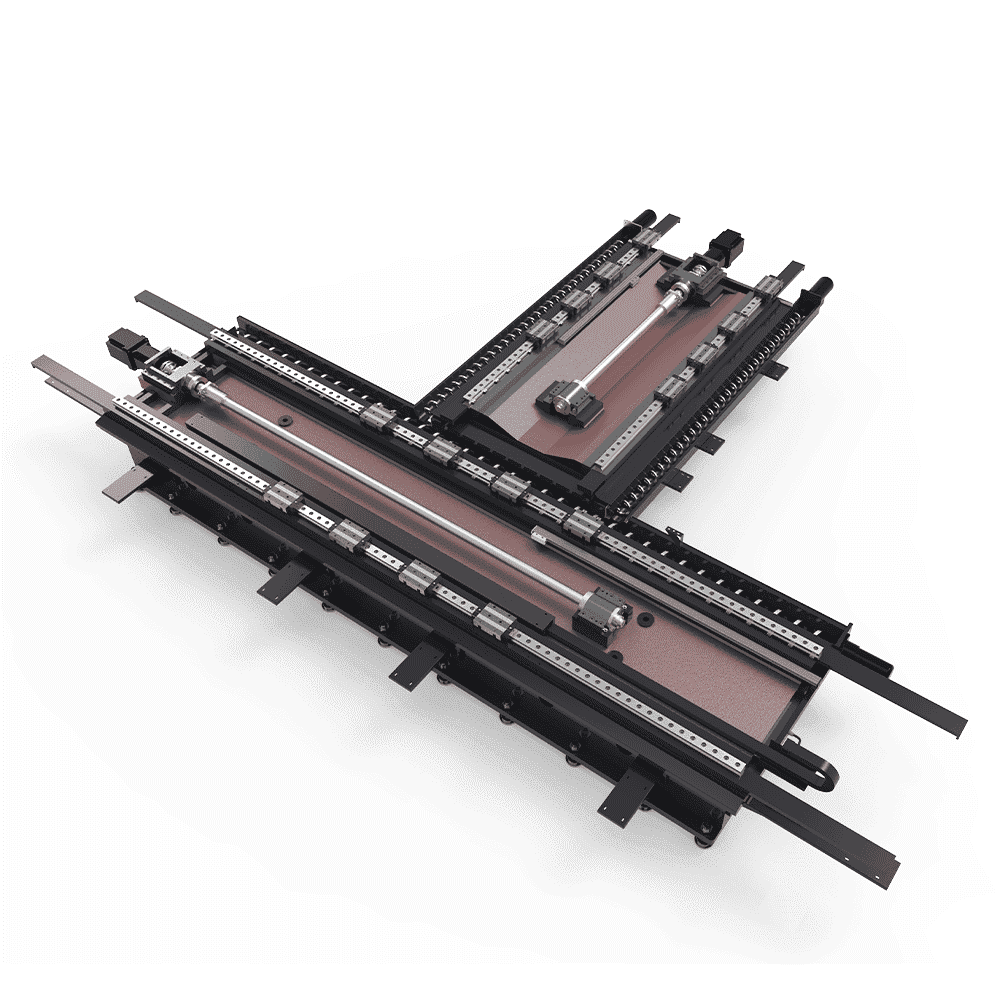

The machine tool features an overs zed invented 'T"-shaped bed base. The Y-axis uses an integrated double-wall moving column design. The spindle box is in a front-mounted configuration.

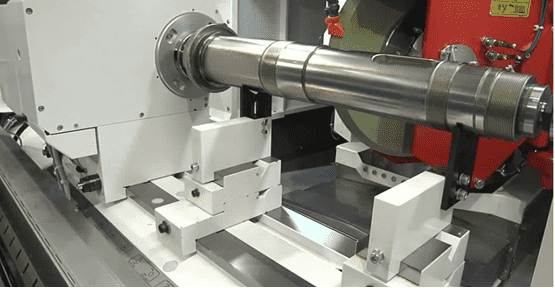

It is heavy-duty cutting and heavy-load, and is a durable tool for rough and finish machining. In order to strengthen roughing, it adopts a customized thickened spindle and is equipped with a 22kw high-torque motor.

The WJ-1815 horizontal machining center is suitable for precision molds, engineering machinery, automobile power, locomotives, ships, ocean engineering and other industries.

In addition, the equipment also adopts advanced technologies and designs such as high-speed spindles and high-precision control systems, further improving machining accuracy and efficiency.

For example, through real-time monitoring and data analysis of the processing of automotive parts, problems in the production process can be identified and solved, improving production efficiency and product quality.

The WJ-1815 horizontal machining center is widely used in the automotive industry. Its high efficiency, precision, and stability have brought great convenience to the automotive manufacturing industry.

The efficient and precise machining capability of WJ-1815 horizontal machining center not only ensures the dimensional accuracy and surface quality of parts, but also greatly improves production efficiency and reduces production costs. Again, from an optimization perspective, horizontal machining centers have also played an important role in the automotive manufacturing process.

The WJ-1815 horizontal machining center is widely used in the automotive industry. Its high efficiency, precision, and stability have brought great convenience to the automotive manufacturing industry. The WJ-1815 horizontal machining center sets a new standard for horizontal machining and provides support for users to achieve sustainable, efficient, and competitive CNC manufacturing in the future.

The WJ-1815 horizontal machining center is designed for high demand components in tool and mold manufacturing, as well as energy and green technology fields, including drive technology for electric vehicles. With its stability, precision, and versatility in processing, it has become the perfect foundation for transformation at all levels of processing. They allow for high process integration, flexible automation, and optimal preparation for digital transformation. In the future, with the further development of the automotive manufacturing industry, we look forward to horizontal machining centers playing a greater role in promoting the progress of the automotive industry.