With the new high of space launches in 2024, the global aerospace industry has once again ushered in a wave of technological innovation. Behind this, CNC machining provides strong support for the development of the aerospace industry with its excellent performance, high precision, and efficiency. Aerospace applications typically require complex and highly specialized components with challenging geometric shapes. The importance of machining centers in the aerospace field cannot be ignored. With its high precision, high efficiency, and strong adaptability, it has become an indispensable equipment in aerospace manufacturing. Machining centers are capable of completing various machining tasks such as milling, drilling, tapping, and cutting, and their high precision and efficiency make them widely used in the aerospace industry.

The importance of machining center in the aerospace field

In the aerospace field, the accuracy of each component is related to the performance and safety of the entire aircraft. Multi axis machining, synchronous milling, and adaptive machining technologies have become key equipment in aerospace component manufacturing. Whether it is the machining of complex components such as engine blades and turbine discs, or the machining of overall structural components and irregular parts, CNC machine tools can achieve precise control to ensure the accuracy and quality of the components.

The materials used in the aerospace field usually have characteristics such as high strength, high temperature stability, and lightweight, such as titanium alloys, high-temperature alloys, composite materials, etc. These materials often have high hardness and cutting difficulty during processing.

In recent years, ASIATOOLS has been focusing on research and development, strengthening the development of high-precision and cutting-edge whole machine products.

The Application of Numerical Control Machine Tools in Aerospace Industry

In the field of aerospace component manufacturing, CNC machine tools have played an important role. Aerospace has high requirements for precision casting of high-temperature alloys, with a high usage rate. Whether it is engine equipment, cabin design, important components of aircraft engines and gas turbines, precision parts are all used.

Secondly, CNC machine tools also meet the processing needs of small batches, multiple varieties, and complex shapes of components, while possessing technical characteristics such as process intensification, flexible processing, and one-time clamping and forming. For example, in the field of engine manufacturing, CNC machine tools have achieved high-precision machining of complex surfaces and micrometer level size control, ensuring the performance and reliability of the engine; In the manufacturing of rocket structural components, CNC machine tools have achieved efficient processing and assembly of the overall structural components, shortening the product manufacturing cycle.

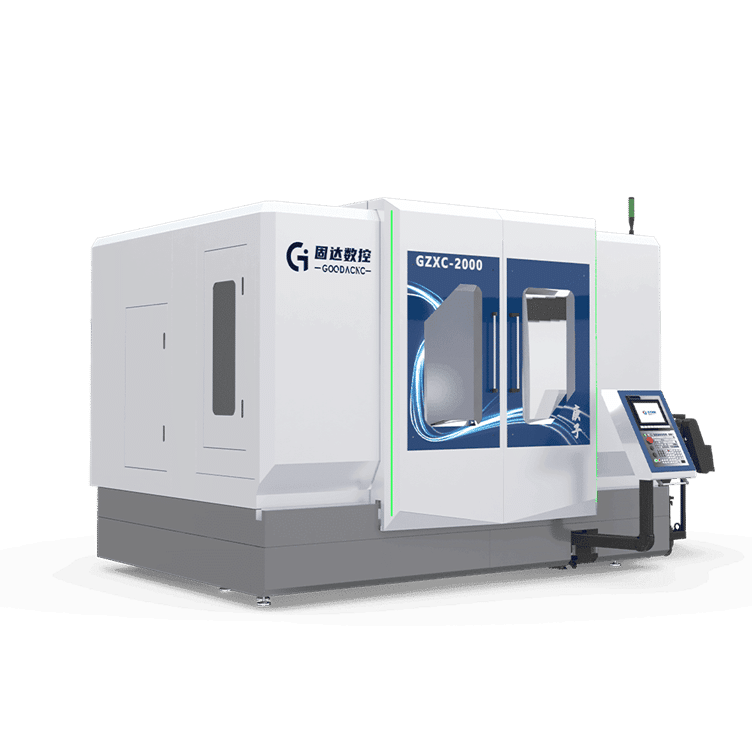

ASIATOOLS 5 Axis CNC Machining Center Case Study in Aerospace Industry

Take ASIATOOLS GZXC-2000 as an example, the 5-Axis multi-tasking machining center comes with a fully digital numerical control device. Integrated with artificial intelligence technology. It includes features such as statistics of screw load in full-lifecycle, intelligent management of tool service life, machine protection functions, QR codes, and self-adjustment of servo parameters, to enhance processing quality, optimize process parameters, and ensure equipment lifespan. It is suitable for fields such as aerospace, automotive, energy, shipbuilding, machine tools, molds, and 3C industries.

Spindle external coolant system

Circulating cooling water with temperature control in the outer cylinder of the spindle bearing part, suppresses the deformation of the spindle due to the heat generated when it rotates at a high speed, thereby preventing changes in machining accuracy.

By circulating the temperature-controlled cooling water in the outer cylinder of the turntable bearing part, the heat generated by the high-speed rotation of the turntable can be suppressed, thereby preventing the change in precision and effectively ensuring the stability of machining accuracy.

Mechanical spindle

The flow of cooling water is managed through strict temperature control in the shaft, which can suppress the heating of the ball screw and the thermal influence from the servo motor.

Milling & lathe integrated spindle

It supports the milling & lathe-integrated spindle unit matching the ATC reducer. The compact design is used to reduce interference, and the processing range has also been expanded. It can be processed with cast iron, 45#, aluminium, titanium and other materials.

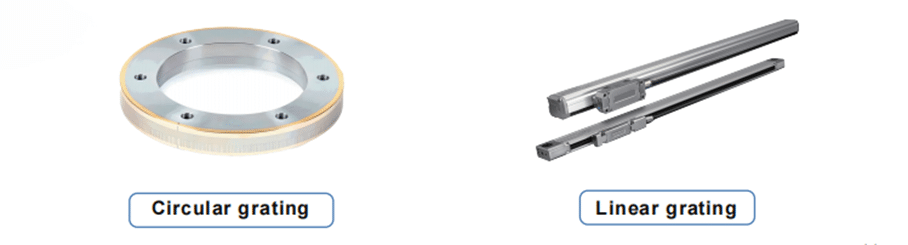

Grating scales

X, Y, and Z axes are equipped with linear grating scales: to detect the actual movement position, and improve the positioning accuracy and repeat positioning accuracy of the machine.

B and C axes are selected circular grating, to ensure the accuracy of the angular position information and improve the position accuracy of the rotary axis.

The 5-Axis multi-tasking machining center development and professional manufacturing - ASIATOOLS

The 5-Axis multi-tasking machining center development and professional manufacturing - ASIATOOLS

ASIATOOLS GZXC-2000 performs excellently in machining complex components such as engine blades and turbine discs. These components have complex geometric shapes and high requirements for material properties and surface quality. Choosing our products not only improves production efficiency but also reduces reliance on physical labor.

If you are looking for a high-quality machining center supplier with reasonable prices, ASIATOOLS is a good choice.