The main differences between CNC duplex milling machines and twin-spindle horizontal machining centers are the degree of automation, processing range and accuracy, equipment cost and maintenance, applicable industries and fields, and the complexity of operation and programming.

What is a CNC duplex milling machine?

CNC double-sided milling machine is a type of CNC machine tool mainly used for milling processing. The main function of a double-sided milling machine includes simultaneously processing both sides of the workpiece, significantly improving production efficiency and machining accuracy. The double-sided milling machine, with its unique structural design, can complete the machining of both sides of the workpiece in one operation, greatly shortening the production cycle and improving production efficiency. However, the replacement of tools in CNC double-sided milling machines requires manual operation, so the automation level of the machining process is relatively low.

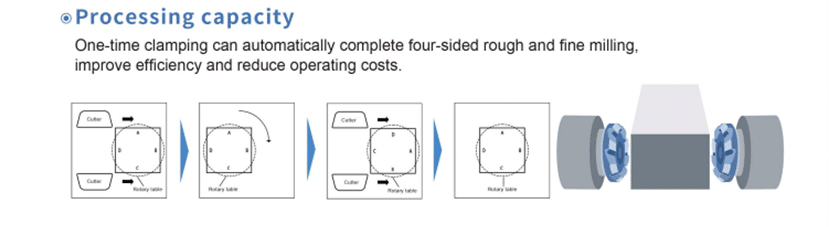

Take ASIATOOLS TH-450 as an example. The machine is equipped with a CNC control system, which can automatically position, measure, and rotate automatically with simple operation and highly intelligent concepts to complete the rough and fine milling of the four sides of workpieces. At the same time, the chamfering process is completed as required.

Suitable for six-sided processing with small margins and centering requirements, such as quenched materials, mold core materials, mold cores, etc.

It has the functions of automatically correcting tool wear, correcting machining errors, and rework.

Regarding processing range and accuracy, CNC duplex milling machines are mainly used for flat milling and partial three-dimensional milling. Due to the need for manual tool replacement, the degree of automation in the machining process is low, which may affect machining accuracy and production efficiency.

The CNC duplex milling machine is suitable for fields with relatively low requirements for machining accuracy and production efficiency, such as general mechanical processing, furniture manufacturing, steel processing industry, mold & die industry and electronic product manufacturing.

What is a twin-spindle horizontal machining center?

A twin-spindle horizontal machining center is a highly automated machine tool that integrates various machining functions such as milling, drilling, and tapping. It is equipped with an automatic tool changing system (ATC), which can automatically change tools during the machining process, thereby achieving continuous operation of multiple machining processes and greatly improving production efficiency.

Due to its automatic tool changing function, the dual spindle horizontal machining center can complete multiple processes in one clamping, reducing the number of clamping times for workpieces and improving machining accuracy and production efficiency.

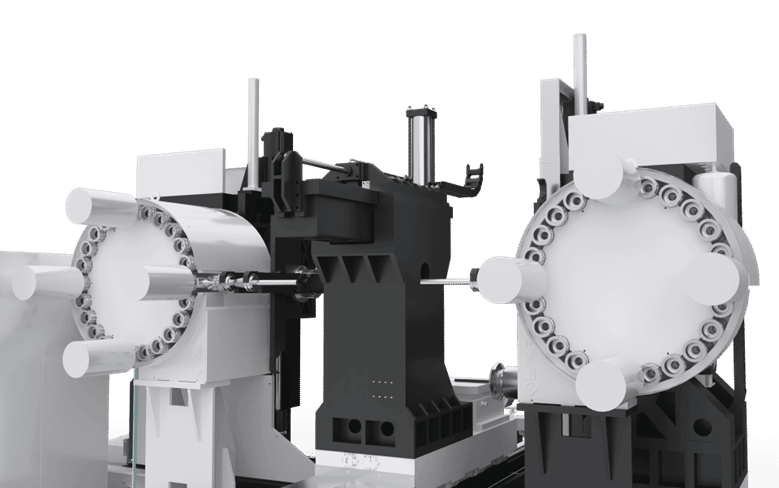

ASIATOOLS TH-600NCH moving column double-head horizontal milling and drilling machine.

The moving column double-head horizontal milling and drilling machine series is mainly used for efficient milling, drilling, and tapping of workpieces with a thickness within the effective range such as large flat plates, wind power flanges, discs, rings, etc. It can drill through holes and blind holes in single material parts and composite materials. The machine tool processing process is digitally controlled and the operation is very convenient. It can achieve automation, high precision, multi variety and batch production to meet the actual needs of users.

High-precision machine tools integrating milling, drilling, and tapping.

The workpiece can be processed in one go (no need for secondary clamping), the loading and unloading, positioning and tool changing speeds are fast, and the processing efficiency is high.

The dual-spindle horizontal machining center is suitable for high-precision and high-efficiency machining fields such as aerospace, automotive manufacturing, mold manufacturing, and medical equipment. It can meet the high requirements of these industries for machining accuracy and production.

The differences between the two machines:

Different processing objects

CNC duplex milling machine tools mainly process rotating bodies, including cylinders, cones, and other objects. A twin-spindle horizontal machining center processes multiple surfaces, with a wider range of processing areas, such as box parts, irregular parts, plate parts, etc.

Cost and maintenance

A twin-spindle horizontal machining center has relatively high equipment costs due to the integration of multiple functions and automatic tool changing systems. At the same time, maintenance and repair are also relatively complex, requiring professional technical personnel to operate. In contrast, CNC duplex milling machines have lower costs and are relatively easy to maintain and repair. General operators can perform these operations after training.

Application

The operation and programming of dual-spindle horizontal machining centers are relatively complex and require professional technical personnel. It is usually equipped with advanced CNC systems that can perform 3D programming and automatic tool change programming to achieve complex machining tasks. In contrast, the operation and programming of a CNC duplex milling machine are relatively simple, and most operators can get started after training.

Get the Best of Both Worlds with ASIATOOLS CNC Duplex Milling Machines & Twin-Spindle Horizontal Machining Centers!

ASIATOOLS, which has been deeply involved in the CNC machine tool industry for many years, the company has a professional technical research and development team and a complete production, sales, and after-sales system, which can provide customers with complete solutions in the field of CNC.

CNC double-sided milling machine developed by ASIATOOLS can complete the four side machining of metal workpieces with only one clamping, greatly reducing the machining time. And our twin-spindle horizontal machining center advanced CNC technology, which can achieve high-precision machining requirements and ensure the stability of machining quality.

If you would like to learn more about CNC machines, please contact us.