Hey there! ASIATOOLS wants to give you a warm reminder.

To ensure the equipment operates smoothly and efficiently, remember to regularly maintain the machine tools.

How to choose a maintenance method suitable for cnc machine tools? Here are nine key steps.

Click on the image below to play the video↓↓↓

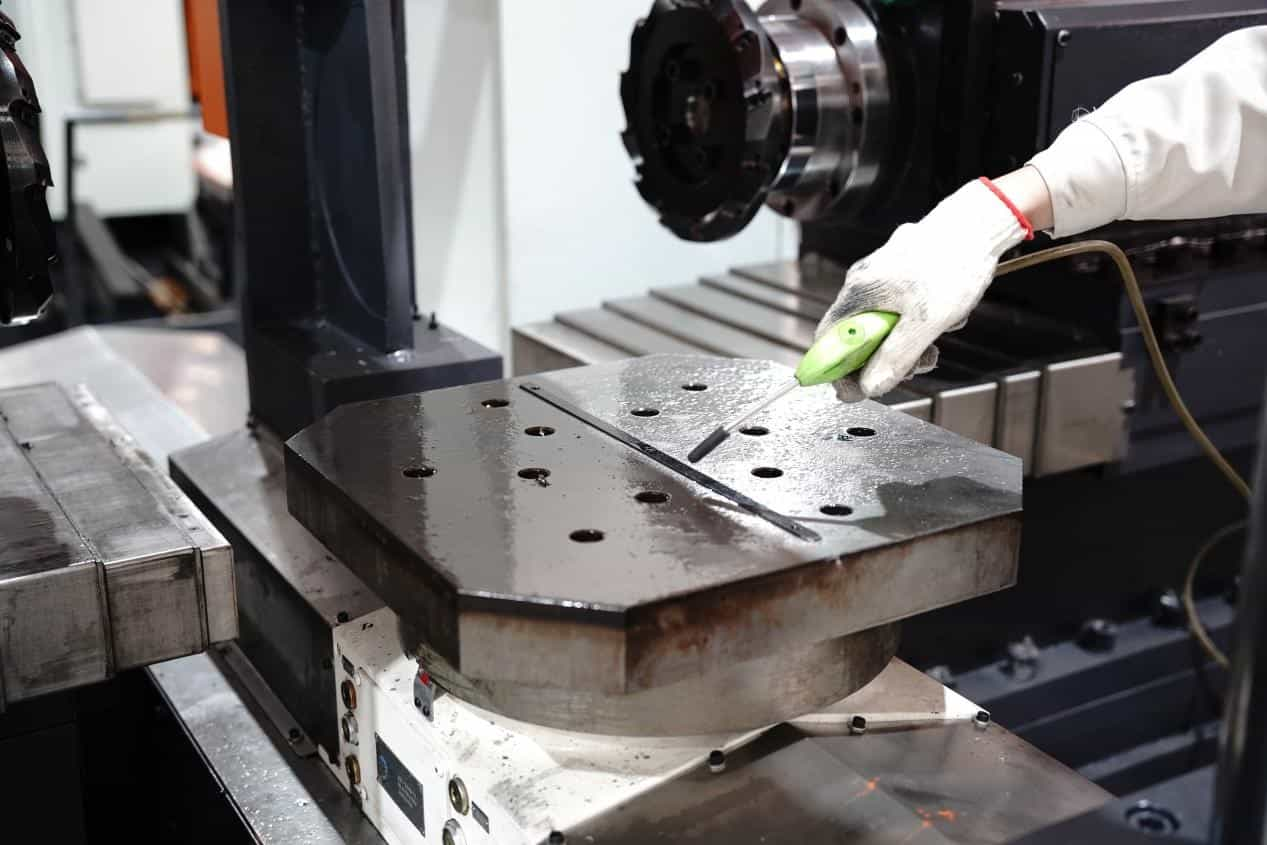

① Clean the processing area.

Clean the workbench, turntable, telescopic protective cover and other processing areas where dust, stains and iron filings are likely to accumulate. Use a clean rag for cleaning, and pay attention to applying oil for rust prevention.

② Clean the guide rails and lead screws.

The main purpose of maintaining guide rails and lead screws is to reduce wear during operation. Therefore, effective lubrication and maintaining daily cleanliness are of utmost importance. Effective maintenance not only ensures the accuracy and speed of the equipment but also extends its service life.

③ Clean the cutter head/spindle and apply rust - proof oil.

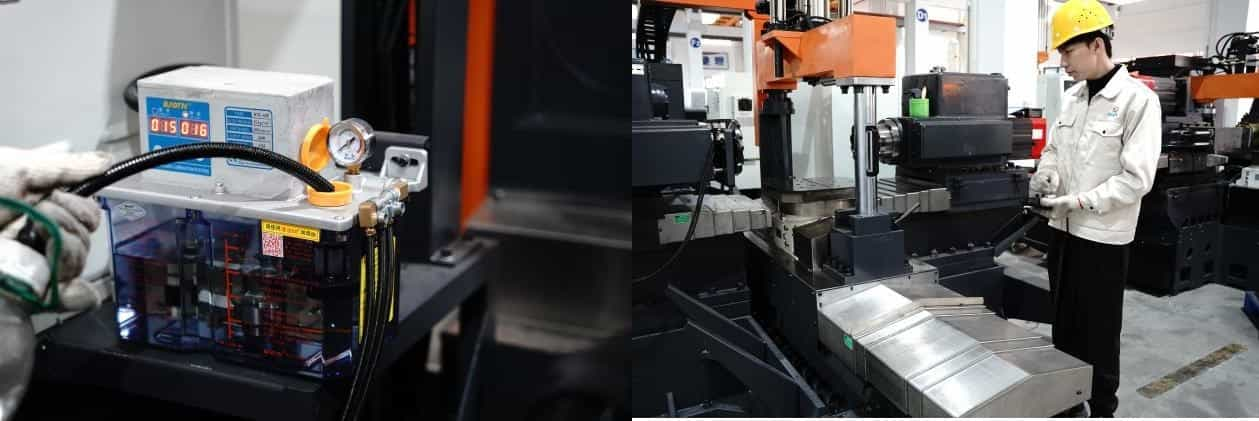

④ Clean the filter screen on the heat exchanger and affix dust - proof adhesive tape.

⑤ Add lubricating oil to the oiler and test the lubrication effect of each axis.

⑥ Check the encoder cable and power cable connected to the servo motor.

⑦ Check if the lines of the driver are loose.

⑧ Axial zero - setting

Make a data backup and confirm whether the mechanical origin coordinates of the CNC machine tools are set to zero.

⑨ Shut down the machine tool, turn off the main electrical cabinet, and close the air source.

If you would like to learn more about our CNC machines, please contact us.