Imagine that when you are still worried about the efficiency bottleneck on the production line, a double-head milling machine has quietly solved all these problems. Today, let us explore the secret of how this machine helps factories greatly improve their work efficiency!

Double power, double efficiency

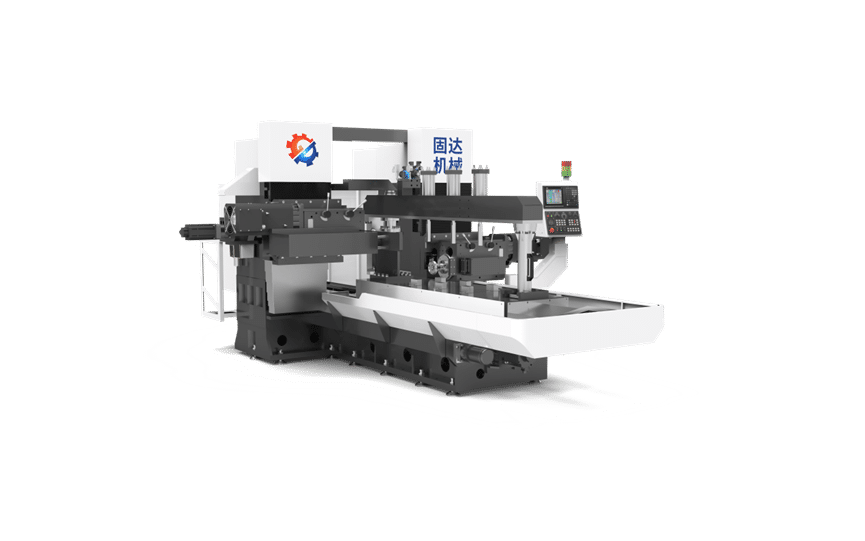

Traditional single-head milling machines need to frequently change tools and adjust the position of workpieces during processing, which undoubtedly increases a lot of non-productive time loss. In contrast, ASIATOOLS double-head milling machine adopts innovative dual-end simultaneous processing technology, which can complete two or more surfaces at the same time, greatly reducing unnecessary waiting time. In this way, the process that originally required two processes can now be completed once, greatly shortening the production cycle and improving the overall production capacity.

Imagine that in the same 8-hour working day, using ordinary machine tools may only complete the processing of 50 parts, but with this double-head milling machine, it can easily achieve 100 or even more! Such efficiency improvement not only means cost reduction, but also a direct reflection of the competitiveness of enterprises.

Accurate positioning, reduced errors

The double-head design not only improves speed but also ensures processing accuracy. Through the symmetrically arranged workbench and clamping system, it can ensure that each workpiece can be processed consistently and accurately, thereby reducing quality problems caused by human operating errors, so that your products can consistently meet high standards.

Flexible switching, strong adaptability

Whether it is complex and changeable small-batch production or large-scale continuous operation, the double-head milling machine can easily cope with it. It can quickly adjust the tool and process parameters according to actual needs, realize the seamless transition from one product to another, and greatly improve the equipment utilization rate and production flexibility.

Energy saving and environmental protection, green production

While pursuing efficiency, we also do not forget to shoulder social responsibilities. The double-head milling machine adopts advanced energy-saving technology, which effectively reduces energy consumption and waste generation while ensuring efficient operation, and contributes to the construction of a green and sustainable industrial environment.

Conclusion

Choosing a double-head milling machine is to choose higher efficiency, more stable quality, stronger adaptability, and lower operating costs. It not only meets the current production needs but also lays a solid foundation for future business expansion. Hurry up and join the ranks of efficient processing, and let the double-head milling machine become the star equipment in your factory!

At the same time, in the fierce market competition, it is also very important to choose a reliable machine tool supplier. As a platform that provides diversified machine tool products and services, ASIATOOLS not only has the best double-head milling products but also provides customers with the best products and services with a sincere attitude.

We are well aware that the needs of each customer are unique. Therefore, ASIATOOLS not only provides a variety of high-end equipment including double-head milling machines, but also is committed to providing tailor-made solutions for each customer. Whether it is from pre-sales consultation to installation and commissioning, or daily maintenance to technical support, we will do our best to ensure that your production process is smooth and unimpeded.